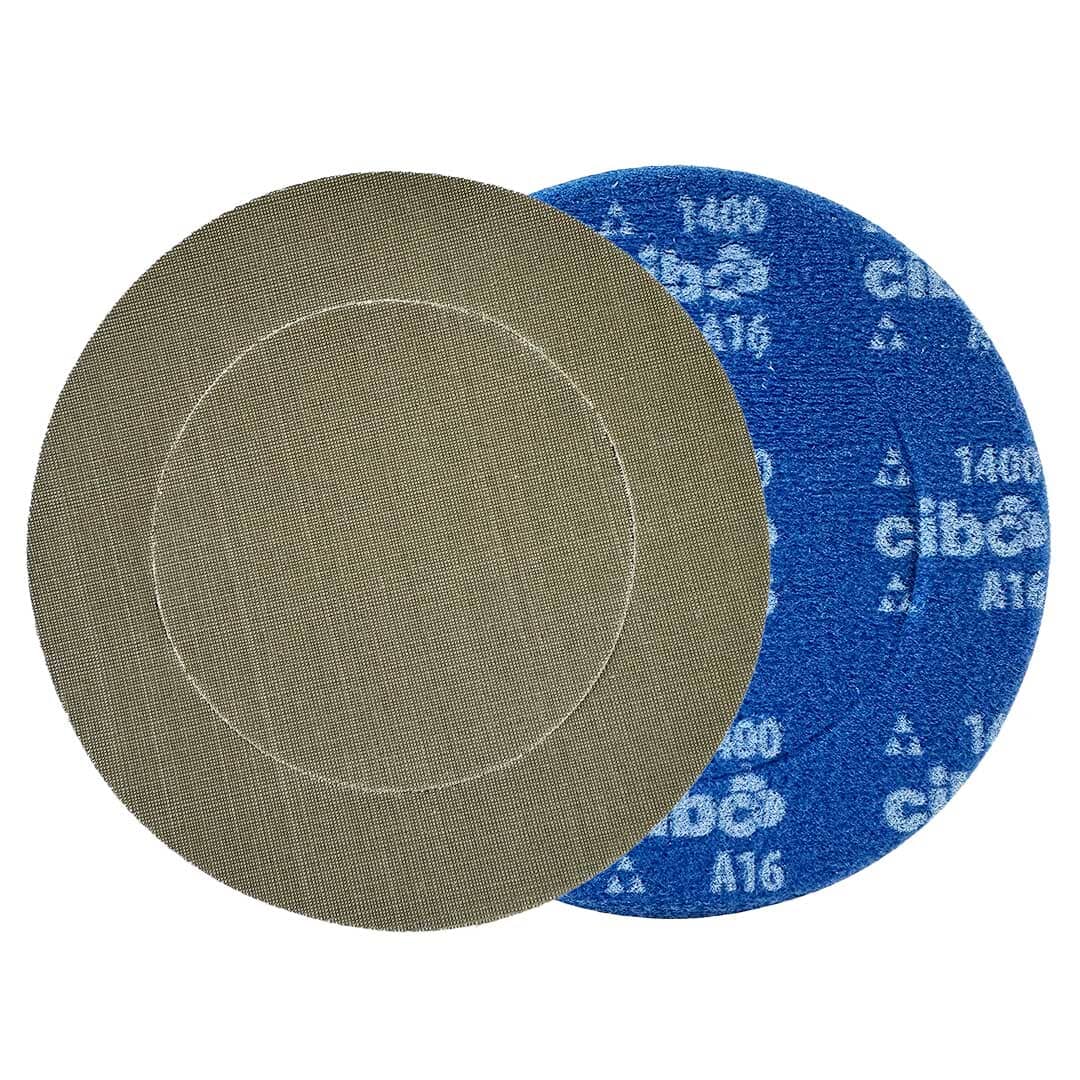

Discover the next level in surface finishing with 3M™ Trizact™ abrasives, engineered using advanced microreplication and macroreplication technologies. Designed for high-performance metalworking applications, Trizact abrasives deliver exceptional control, consistency, and surface quality—reducing steps, time, and cost in your finishing workflow.

🔬 What Is Microreplication?

Trizact Microreplication is the precision-engineered process of forming identical pyramid-shaped abrasive structures. Each grain is:

-

Uniform in height

-

Evenly spaced

-

Perfectly calibrated

This ensures controlled surface contact, consistent finish depth, and minimal risk of deep scratches or gouging—even on delicate materials. Microreplicated abrasives renew continuously, revealing fresh abrasive layers for extended performance and minimal pressure during use.

🧱 What Is Macroreplication?

Trizact Macroreplication forms 3D structures using compressed abrasive grains, evenly distributed over the entire disc or belt. This design allows:

-

Stable cutting action

-

Uniform wear

-

Predictable material removal rates

🛠️ Trizact Abrasives – Application Areas

Trizact abrasives are purpose-built for precision finishing, especially on:

-

Hard-to-process metals like titanium, cobalt, and stainless steel

-

Exotic alloys used in aerospace, medical, and industrial engineering

-

Non-ferrous metals like aluminium, bronze, and copper

-

Composite and synthetic materials in automotive and manufacturing

🔎 Note: Trizact is designed for finishing and polishing, not for heavy-duty deburring tasks.

🔧 Trizact Product Range Overview

| Trizact Product | Technology Type | Use Case | Recommended Use | Water-Resistance |

|---|---|---|---|---|

| 237AA | Microreplication | Fine finishing | Dry | ❌ |

| 217EA | Microreplication | Satin to pre-polish finishes | Dry | ❌ |

| 337DC | Macroreplication | Grind + finish in one step | Dry | ❌ |

| 953FA | Macroreplication | Wet grinding & finishing | Wet | ✅ Waterproof backing |

💡 Key Features of Trizact Technology

-

Uniform Grain Height: Delivers smooth, even finishes without deep grooves

-

Consistent Abrasive Density: Same number of cutting points from start to finish

-

Self-Renewing Structure: Extends disc life and reduces abrasive changeover

-

Low-Pressure Efficiency: Achieve superior results with minimal effort

-

Controlled Surface Contact: No overcutting, no burrs, no scratches

✅ Benefits of Using Trizact Abrasives

-

🚫 No deep or uneven scratches

-

📏 Precision-level uniformity

-

🔄 Repeatable, consistent finish quality

-

⏱️ Faster results with fewer steps

-

💰 Lower total cost per finished part

-

🔧 Less tool wear & fewer rework issues

-

♻️ Reduced waste and energy consumption

🏭 Industries That Rely on Trizact Abrasives

Trizact abrasives are trusted across industries where finish quality and consistency are critical:

-

Stainless steel polishing & linishing

-

Medical implants & surgical components

-

Turbine blade finishing

-

Precision industrial tooling

-

Tank, boiler, and pressure vessel fabrication

-

Architectural metal (doors, windows, balustrades)

-

Copper & bronze tubing

-

Composite parts for aviation & automotive